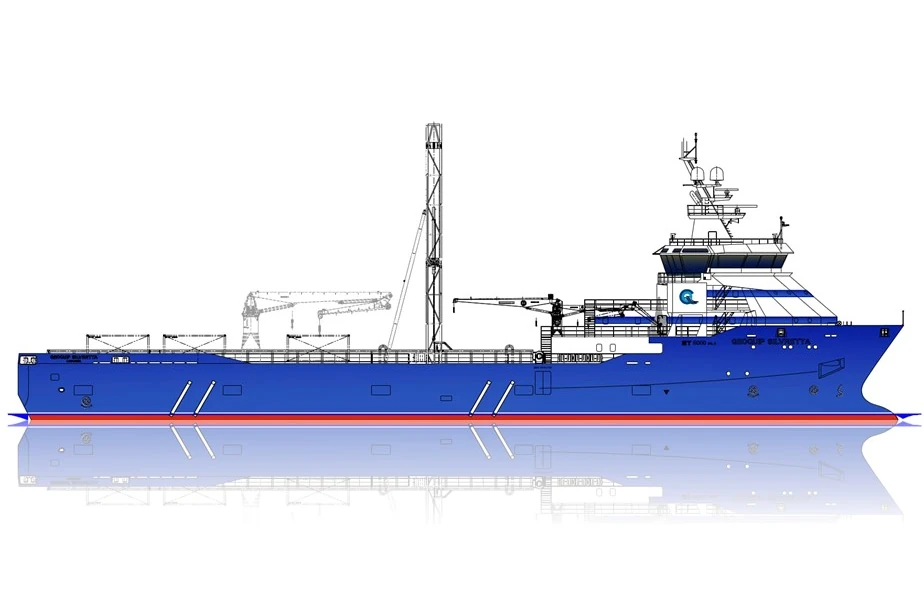

GEOQUIP SILVRETTA

GEOQUIP SILVRETTA + GMTR150

+ GMTR150

A STABLE DEEPWATER GEOTECHNICAL PLATFORM

The Geoquip Silvretta is a state-of-the-art DP2 geotechnical vessel designed by Marin Teknik and built by Kleven Verft. Her MT 6000 hull features a broad 20-metre beam which, combined with a drop-down Azimuth thruster and multiple independent references (DGPS, Fanbeam, and HiPAP), ensures exceptional stability and station-keeping. Furthermore, the vessel’s diesel-electric propulsion is optimised for fuel economy, reducing the environmental footprint during transit and operations.

Permanently mobilised with the GMTR150 heave-compensated marine drill rig over a central moon pool, the vessel leverages over 30 years of design evolution to ensure operational reliability. This setup provides a stable platform for deepwater sampling and testing, incorporating automated pipe and tool handling systems to maximise safety and efficiency on deck.

ON-BOARD SYSTEMS

ON-BOARD SOIL LABORATORY

The Geoquip Silvretta features a dedicated onboard soil and rock testing laboratory. This facility enables our geotechnical engineers to classify recovered samples and determine strength parameters for design and analysis in real-time. Leveraging this data, we can perform spudcan penetration and pile capacity/installation engineering analyses as the borehole progresses. This immediate insight allows for the optimisation of the final borehole depth, resulting in savings in operational time and cost.

The laboratory is equipped with the necessary tools to conduct standard soil and rock tests, with routine workflows covering sample handling, photography, classification, and storage. The testing schedule can be tailored to your project, and high-quality samples can be retained in Shelby tubes to support advanced onshore laboratory testing requirements. All recovered samples are stored in a temperature-controlled environment prior to shipment to an onshore facility.

SEABED SYSTEMS

The Geoquip Silvretta can operate Geoquip Marine’s GMC201 20T deep push seabed unit to conduct an array of in situ tests safely and efficiently.

When your project requires in situ testing, in either shallow or deep water, the GMC201 seabed unit can be deployed rapidly, offering shorter turnaround times and reduced operational costs. Featuring a 20t deep push CPT system with a straight rod push thrust mechanism, the unit allows for the recording of in-situ data to 40 metres below the mudline or greater, depending on soil conditions.